In today’s fast-paced retail landscape, efficient inventory management plays a pivotal role in ensuring customer satisfaction and maximizing profitability. Walmart, one of the world’s largest retailers, is embracing Radio Frequency Identification (RFID) technology as a powerful tool to optimize its inventory management.

By implementing RFID, Walmart aims to streamline operations, improve inventory accuracy, and enhance the overall shopping experience for its customers. This article delves into Walmart’s utilization of RFID, its impact on suppliers, and the collaborative efforts taking place within the retail industry.

The RFID Conference: A Showcase of Walmart’s Commitment

Recently, Walmart hosted an RFID conference that witnessed an impressive turnout of both suppliers and vendor partners. This event provided a platform for Walmart to reinforce its dedication to leveraging RFID technology for better inventory control. The conference showcased Walmart’s proactive approach to embracing innovative solutions and creating a more efficient retail environment. Dan Hare attended this conference on behalf of Apis Wise. Dan has been a solution subject matter expert and sales consultant to manufacturing customers for nearly 30 years. This article is his take away from the conference.

Customization and Tag Placement

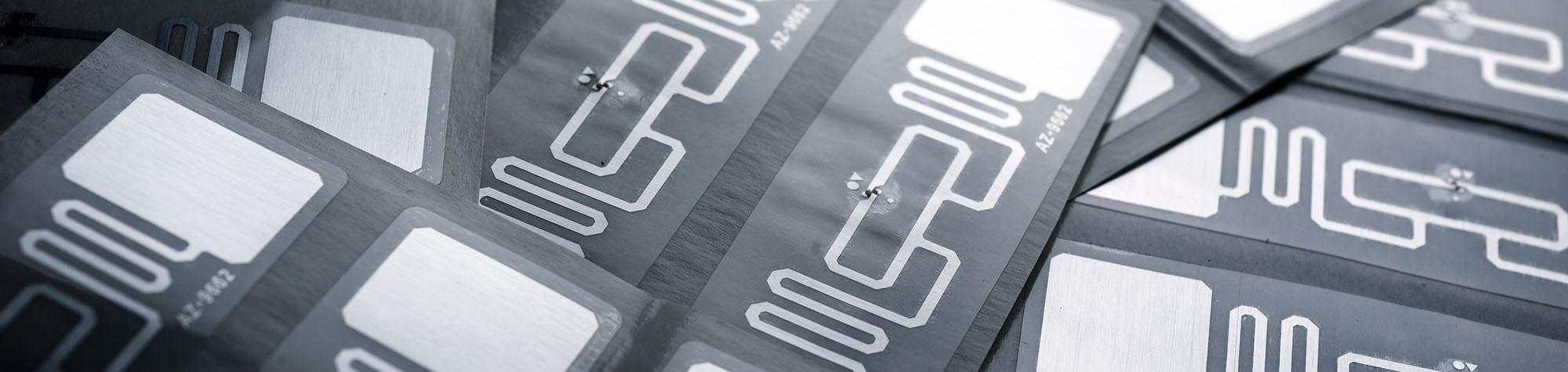

While the RFID frequency used by Walmart is standardized, the tags themselves are not. Walmart requires each of its vendors to send their products to the University of Auburn, which plays a crucial role in determining the optimal tag placement and design for each item. This customization ensures the best possible performance of the RFID system within Walmart’s stores. In some cases, vendors may even need to create customized tags for their products to ensure seamless integration.

Balancing Sustainability and Technology

Walmart’s commitment to sustainability raises concerns among suppliers regarding the environmental impact of RFID tags. Suppliers question whether products can still be recycled with an RFID tag attached. To address this, Walmart is exploring the use of removable tags when necessary, allowing for recyclability without compromising inventory management efficiency. Additionally, products that cannot accommodate suitable tags may receive exemptions from the RFID mandate.

Infrastructure Challenges and Internal Value

As suppliers gear up to meet Walmart’s RFID requirements, concerns arise regarding the short timeframe and necessary infrastructure upgrades. Suppliers may need to invest in new labelers, readers, conveyors, and other equipment to facilitate smooth RFID implementation. Despite these challenges, suppliers are also recognizing the potential for gaining internal value through the mandated adoption of RFID. The enhanced inventory visibility and operational efficiencies associated with RFID implementation can lead to cost savings and improved supply chain performance.

Considerations for Manufacturers

For manufacturers operating at high speeds, the application of RFID tags raises concerns about potential line slowdowns and increased line stops during the tagging process. These apprehensions arise due to the time and precision required to attach RFID tags to products accurately. However, as manufacturers explore strategies to mitigate these challenges, they acknowledge the long-term benefits of RFID integration, including improved inventory accuracy and reduced losses.

Collaboration and Industry-Wide Adoption

Walmart’s efforts to adopt RFID technology are not isolated. Retail giants such as Dick’s Sporting Goods and Macy’s are also embracing RFID for enhanced inventory management. These companies, along with Walmart, are actively collaborating and sharing insights to drive industry-wide adoption of RFID. The University of Auburn, acting as a central hub, is facilitating this collaboration and ensuring the standardization of RFID tags across participating companies.

Future Prospects and Tag Vendor Approval

The success of Walmart’s RFID implementation has garnered attention from other industry players, prompting them to consider rolling out their own RFID mandates. This growing interest indicates a potential industry-wide shift towards RFID technology as a standard practice for inventory management. To ensure consistency, all tags used by collaborating companies will adhere to the same frequency. Walmart, alongside other retailers, is actively promoting approved tag vendors, with the approval process overseen by the University of Auburn.

Conclusion

Walmart’s enthusiastic adoption of RFID technology marks a significant milestone in the evolution of inventory management. The company’s commitment to sustainability and collaboration sets a benchmark for other retailers to follow.