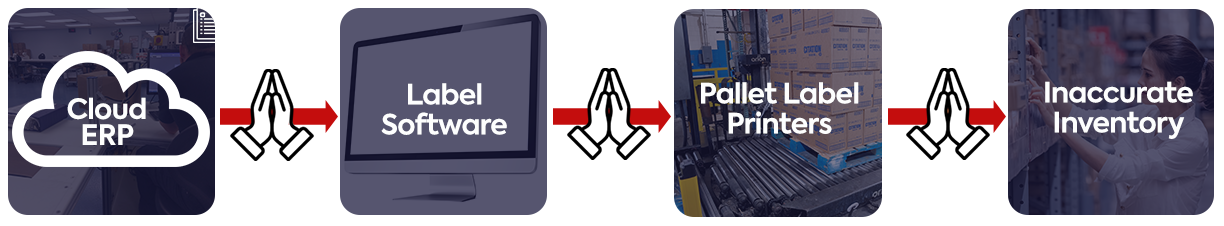

Many companies are instructed by their Enterprise Resource Planning (ERP) and warehouse management (WMS) software vendors that printing from their software through label software to pallet label printers is their only option. This method should be called “Print to Hope.”

The enterprise software, which is often cloud based, sends pallet data to the label software to print pallet labels. Every time a label request is created, a goods receipt reports production, draws down on WIP, and generates an inventory record for the pallet. The label software then hopes a label is actually printed.

If these disconnected systems get lucky and print, many times there aren’t controls in place to ensure the label is applied to the correct pallet. In addition, discarded, unused labels generate phantom inventory. This overreports inventory and disrupts every segment of your business. This is when the following questions often arise.

- What if the data never gets to the label software?

- What if the print job never gets to the printer from the label software?

- What if the employee applies the labels to the wrong pallets or they throw them out without reversing them out of inventory?

In a perfect world, this process should work great! However, the issues arise when the ugly exceptions of the real world occur. A label wads up in the printer, labels fall on the floor and are never applied, the print file never makes it to the printer, or the operators batch print labels which create phantom inventory.

These exceptions happen daily, and many companies often overlook the extent of labor wastage involved in addressing these issues. It’s only when the individuals responsible for managing these challenges are no longer available that the true impact of this oversight becomes apparent.

There is a better solution, a proven one which has been perfected over the past 25 years across fortune 500 companies throughout North America.

Click here to learn about the proven Pallet Labeling Intelligence solution by Apis Wise.